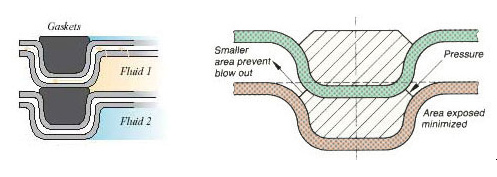

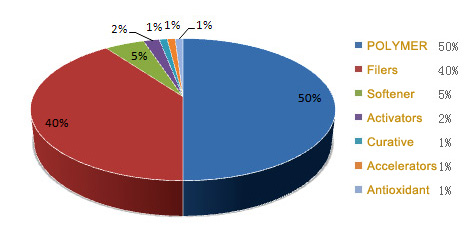

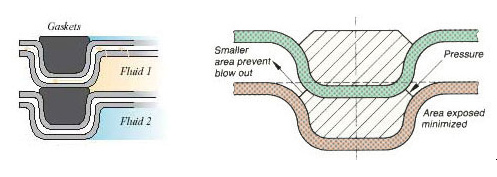

Incompressibility

The rubber compound can change shape, so that after being squeezed it will return to its original vulcanized shape.

Strength

It is strong enough to withstand the forces normally incurred by squeezing into position and being acted upon by pressurized liquid.

Softness

This is adjusted by compounding so that the rubber is strong enough for the application but still soft enough to conform closely to the metal surfaces and provides a seal without undue stresses being applied.

Resistance to Fluid

The high molecular weigh, cross linked polymer matrix is resistant to penetration by any fluid of a dissimilar chemical nature to itself.

Resistance to Temperature

All polymers will only behave as a rubber over a relatively short range of temperature. Thus careful selection of the compound according to the required temperature range is vital.

Longevity

Synthetic polymers have a built in superiority in terms of useful lifetime, and modern additives can further enhance this property. It is in this area that the correct compound selection is of vital importance.

|